How to determine whether jaw crusher parts need to be replaced

Jaw crusher is a commonly used crushing equipment, widely used in mining, construction, highway and other industries. During the operation of jaw crusher, the wear and tear of parts is an unavoidable problem, and timely replacement of damaged parts is crucial to ensure the normal operation of the equipment. So, how to determine whether the jaw crusher parts need to be replaced? The following is a detailed introduction for you:

First, the appearance of the crusher and the operating environment check

First of all, we need to make a preliminary inspection of the appearance and operating environment of the jaw crusher. Observe whether the crusher shell has obvious deformation, cracks or corrosion; check whether the connecting parts are tight, whether there is any looseness or breakage; at the same time, we also need to pay attention to the operating environment around the crusher to see whether there is accumulation of dust and sundries, which may have an impact on the normal operation of the crusher.

Second, the degree of wear and tear of parts assessment

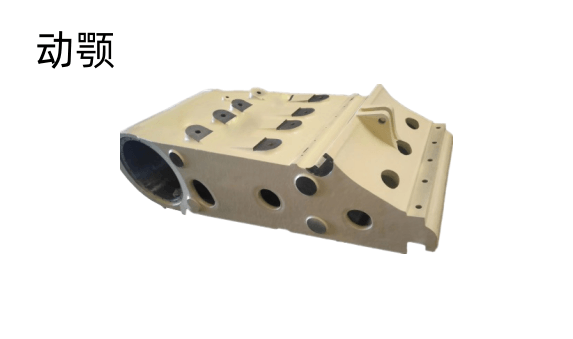

1. Jaw plate wear inspection

Jaw plate is the core component of the jaw crusher, and its wear level is directly related to the crushing effect and the operation stability of the equipment. When checking the jaw plate, pay attention to the wear of the jaw teeth, such as whether the jaw teeth are broken, detached or severely worn, and whether the surface of the jaw plate is uneven or severely worn. When the jaw teeth are worn to a certain extent and cannot effectively crush materials, it is necessary to replace the jaw plate with a new one in time.

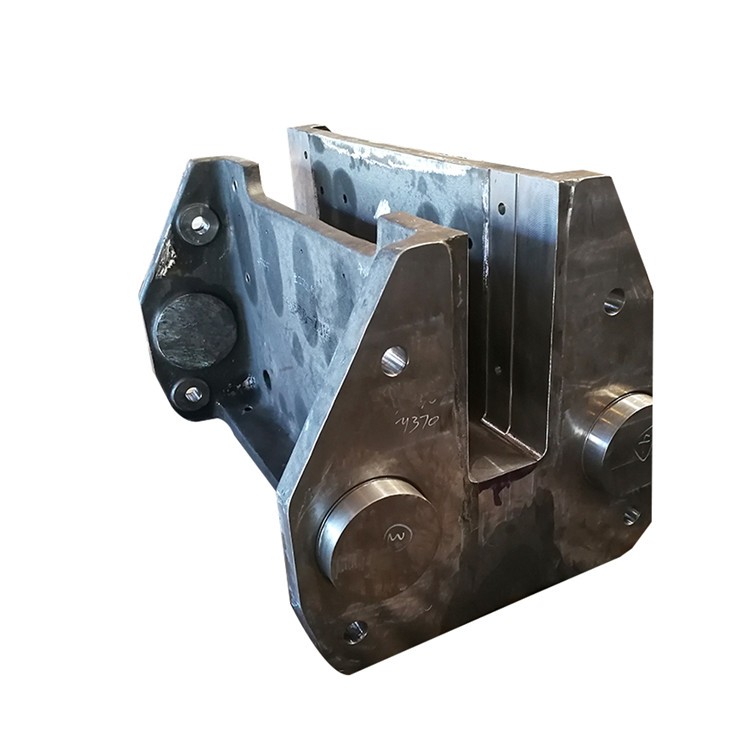

2. Inspection of bearings and transmission parts

Bearings and transmission parts are important transmission parts of the jaw crusher, and their operation status directly affects the overall performance of the crusher. When checking the bearings, pay attention to the lubrication condition, running sound and temperature of the bearings. If the bearings are running inflexibly, sound abnormally or temperature is too high, it may be a sign of bearing wear or damage, and need to be replaced in time. At the same time, the connection of transmission parts should also be checked to ensure smooth transmission and no abnormal vibration.

3. Eccentric shaft and flywheel inspection

Eccentric shaft and flywheel are the key parts of the jaw crusher, and their operation status is directly related to the crushing capacity and stability of the crusher. When checking the eccentric shaft, pay attention to whether there is any crack, wear or deformation on its surface. The inspection of flywheel, on the other hand, focuses on its balance and integrity. If the flywheel is unbalanced or seriously worn, it should be replaced in time to avoid equipment failure